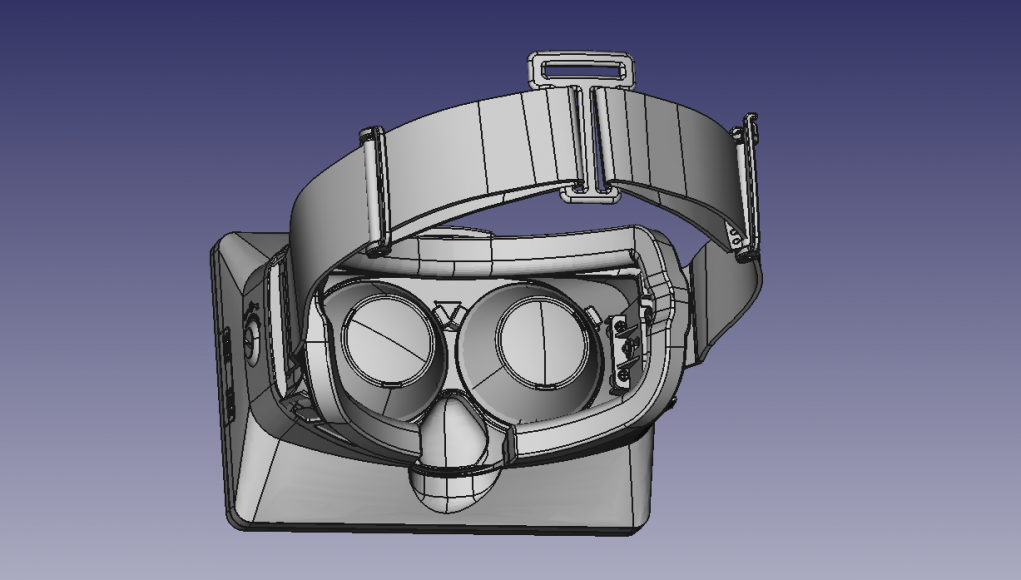

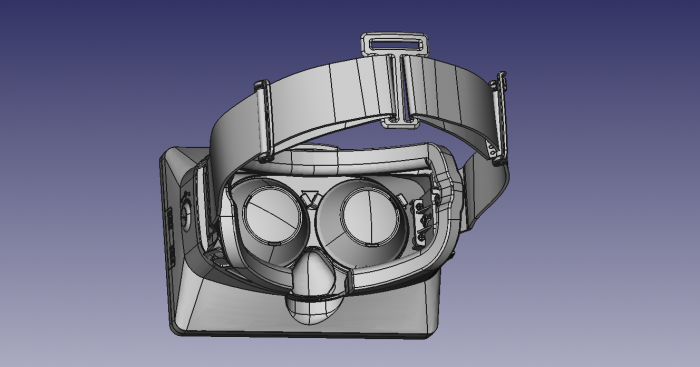

During a session at Oculus Connect, the company released the totality of the Oculus Rift DK1 plans to the public. Under an open-source license, anyone can now freely download the blueprints of the company’s first VR headset and even manufacture their own.

At Oculus Connect during a session called Building the First Rift Development Kit, Oculus Engineer Nirav Patel spoke about the challenges associated with the company’s first VR headset, the DK1.

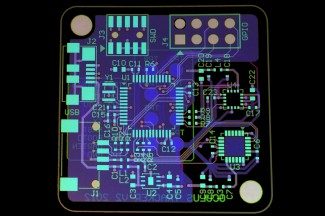

At the end of the session, Patel, on stage in front of the audience, logged into the Oculus GitHub account to hit the publish button on the repository containing the essential elements of the DK1, including firmware, circuit board and mechanical designs, and the accompanying documentation.

“Ok that’s it, it’s public,” Patel said, followed by audience applause. The files are available here.

All of the DK1 plans are released under the Creative Commons ‘Attribution 4.0 International’ license which permits the following uses:

Share — copy and redistribute the material in any medium or format

Adapt — remix, transform, and build upon the materialfor any purpose, even commercially

So long as:

Attribution — You must give appropriate credit, provide a link to the license, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

Patel said that, for instance, anyone could take the tracker design, manufacture their own product based on it, and even sell it.

“I can’t wait to see all of the Chinese knockoffs… God help us all,” Oculus CEO Brendan Iribe teased during his keynote presentation the following day. “But we do believe that this is important. It’s important for the hackers and the makers out there to be able to pick this up, take that tracker, glue it on to different things… take some source code, change it, modify it, ship it, make something awesome.” he continued.

Manufacturing the Oculus Rift DK1

While backers of the Oculus Rift Kickstarter ended up with what looked to be a polished DK1 development kit, the at-the-time 10 person company had little experience in manufacturing and shipping a hardware product. Patel, a former Apple software engineer, elaborated on the manufacturing process and its challenges during his session.

“We knew we couldn’t scale up an engineering team in time to solve all the tough manufacturing problems,” Patel said. “This is one of the big places we had to take a risk on—letting worse be better in some cases. We needed to find a manufacturing partner that we could lean on.”

Speed was a major concern. The company aimed to have the DK1 shipped some five months after their 2012 Kickstarter. “Our initial ship date was December, but this turned out to be incredibly unrealistic. Even our later date was really aggressive,” said Patel.

With a design that lacked important specifications, like the type of foam that should pad the unit from the user’s face, Oculus made several trips to China to work directly with their manufacturer to make changes and evolve the design into something that could be mass produced.

“We found just about the roughest and quickest contract manufacturer in China,” said Patel. “They took a big bet on us just like we took a big bet on them.”

Oculus had to find creative solutions to challenging problems. They found that they couldn’t send the expensive rate tables, a spinning apparatus used to calibrate trackers, to China—perhaps because the trackers often calibrated with such tables find their way into military equipment. Instead, Oculus rigged up some turntables to be computer-controlled and used them in the calibration process.

Some issues remained, including a gyroscope problem that was doubling error instead of correcting it, fortunately they were able to fix it through firmware after the units had been shipped out.

The young company also had to deal with a major change while working on the manufacturing process. The 5-inch screen to be used was discontinued and they had to scramble to find an alternative. They ended up with a 7-inch display which meant making adjustments to the design of the DK1.

“We had this mad rush to switch to a 7-inch panel… it meant that the panel didn’t match the rest of the design, including the optics. But it was a tradeoff we made for the sake of getting units out the door and content made as quickly as possible,” said Patel.

However inexperienced, the company pulled through and had the first batch of DK1s manufactured in time for GDC 2013.

“The initial risk paid off, the kit was good enough at the right things. Patel said. “We were able to turn a lot of people into believers in that one day [at GDC 2013], despite the 1 hour wait.”