DigiLens, creators of waveguide optics, today announced a “deeper” partnership with Mitsubishi Chemical to bring a plastic version of its waveguide technology to the market. The companies claim the plastic variant achieves “nearly the same” performance as its glass counterpart, while being lighter, cheaper, and safer, with the ultimate goal of enabling a “consumer price point” for AR glasses.

DigiLens is among a handful of waveguide makers competing to position themselves as the best optical solution for a forthcoming wave of consumer-focused AR glasses.

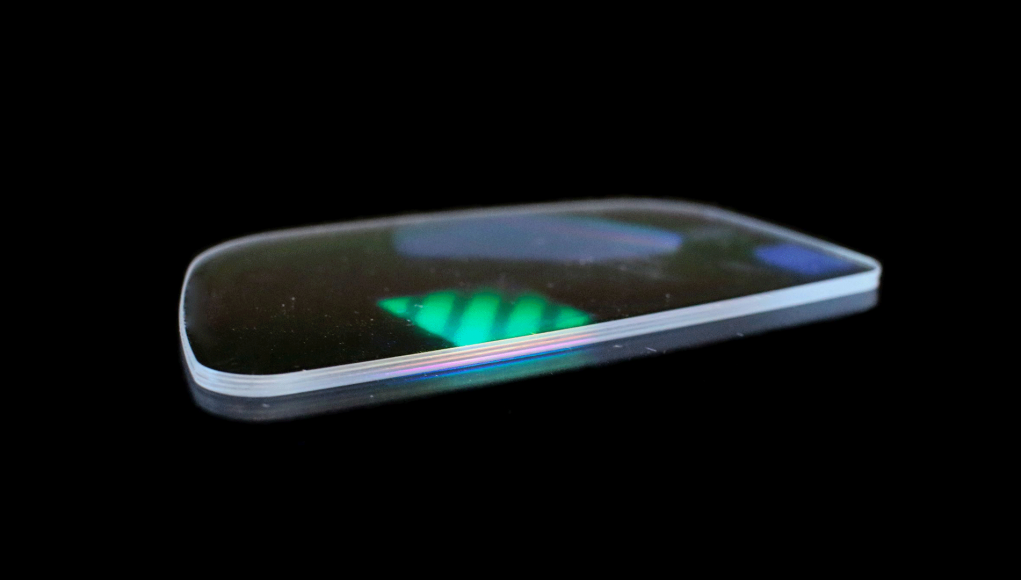

The company’s waveguide tech uses a photopolymer manufacturing process which involves forming light-guiding nano-structures (gratings) in a thin film that’s encased in glass. As light enters the waveguide from a source, it is redirected by the gratings, bounced along the glass, and then redirected by another set of gratings to reach the user’s eye, enabling an incredibly thin and light optic.

Thanks to its optical characteristics, glass is employed by most waveguide makers, even though it’s expensive. In an effort to make waveguide manufacturing more affordable, DigiLens today announced that it is ready to begin offering a plastic version of its waveguides, thanks in part to a “deeper partnership” with Mitsubishi Chemical—which is an existing investor in the company and likely a provider of the plastic used in the new waveguides.

DigiLens claims it’s making the “first-ever” plastic waveguides suitable for AR applications that don’t require nanoimprint lithography (another, ostensibly more costly, manufacturing process). The company also says the plastic versions “perform at nearly the same level as glass,” while reducing cost, weight, and increasing safety for hazardous use cases (ie: protective eyewear).

DigiLens isn’t giving a clear picture of the scale of cost reductions from the move to plastic, though considering the company is hoping to supply waveguides for mass manufacturing, even small savings can add up over time.

The company is, however, setting clear expectations for weight differences. The glass variant of the DigiLens Crystal30-G waveguide weighs in at 4.39 grams, while the plastic variant is just 2.73 grams (almost 50% less), despite being 27% thicker.

While a few grams lighter seems like it would be trivial, in an space where AR glasses would ideally weigh no more than 80 grams, saving 1.7 grams per lens starts to add up, especially as lenses grow larger with demand for a wider field-of-view.

– – — – –

While DigiLens doesn’t want to actually make AR headsets itself, earlier this year the company announced a hardware development kit called the Design v1 to help accelerate the consumerization of AR glasses by making it easier for other companies to experiment with their own headset designs—which would include DigiLens waveguides, naturally. We got to check out the Design v1 headset in an exclusive hands-on.