German car maker Audi was quick to see the potential of VR and has been experimenting since the early days of VR’s resurgence to see how the tech could be used to enhance the car buying experience. Having introduced VR showrooms into dealerships as early as 2016, the company now has some 1,000 VR deployments in dealerships across the globe.

Speaking on stage last week at VRX 2018 in San Francisco, Audi’s Lorenz Schweiger, who looks after VR strategy at the company’s Business Innovation group, explored Audi’s ongoing work in bringing real-time VR visualizations into dealerships.

As Schweiger explained, the company has built a VR offering which acts as a virtual car configurator. Users strap on a headset and can view detailed car models at life size, with the ability to look at specific colors and configurations on the fly.

Audi has maintained a high bar for the VR visuals that is shows to customers, and that’s meant using the master vehicle models—developed throughout the car’s engineering and construction processes—as the basis for the visualization. As those models contain every single panel, screw, fastener, and fuse in the vehicle (and those for various configurations) they are far too complex to be rendered in a real-time VR visualization, Schweiger explained.

And so the company had developed a process of reducing the complexity of the models by hand to the point at which they could be rendered in real-time against the 90 FPS demands of modern VR headsets—a process which took one to two weeks for a single vehicle.

But that bottleneck—of converting each year’s new lineup of vehicles—was a pain point for making the company’s VR deployments effective. Schweiger and his team sought a means of automating the process of optimizing the models until they could be rendered in real-time.

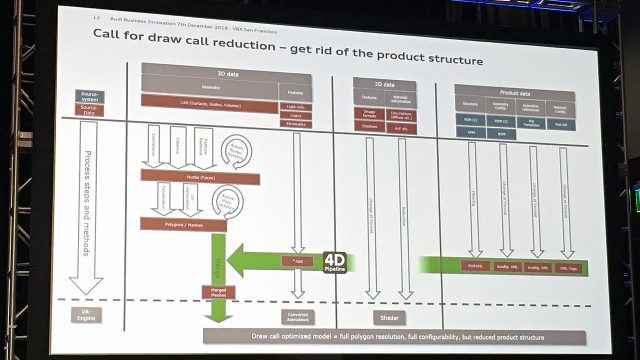

Some solutions which focused on automatically reducing the model’s geometric complexity resulted in an unacceptable sacrifice of the model’s visual quality. Wanting to keep visual quality high, Audi worked with a company called 4D Pipeline to develop a solution which would greatly reduce the complexity of the models by combining the many individual pieces into larger pieces, there by drastically reducing GPU draw calls while keeping geometric detail in tact.

And the results are very impressive indeed. Schweiger showed a handful of screenshots and flyby videos of the optimized models—which are ready to be rendered in VR at 90 FPS—revealing a very crisp look with realistic lighting, reflections, and interactions (like opening & closing doors and turning on & off headlights), both inside and outside of the vehicles.

The 4D Pipeline solution reduced the previous manual optimization process from one to two weeks per vehicle down to just 20 minutes, said Schweiger. The process also works directly from Audi’s master vehicle files, which means that if anything in those models were to change in the 11th hour, the process could quickly be re-run without ruining any additional work that had gone into the optimized models after the fact.

What’s more, the process also works with vehicles from Audi’s parent company, Volkswagen, because between the two companies the master vehicle files are based on the same structure, he said.

As the company continues to harness VR to create a more engaging sales experience, Audi has now deployed VR showrooms to some 1,000 dealerships, said Schweiger. The company has also previously said that it employs VR technology internally from sales & training to technical development & automotive production.