3. Assemble the Foam-Core Case

If you have a 3D printer you can use this incredible 3D-printed case by WickedAndy instead of building the foam-core case described below.

Next it is time to assemble the foam-core case. Before you get started please take a minute and make sure your X-Acto knife is sharp and clean, doing so will make the following steps much easier!

If you have never worked with foam-core before, I recommend that you cut a small piece from your sheet to practice some straight cuts using the steel ruler. It is not hard, but it takes a few cuts to get the hang of it.

Download the Cutting Template

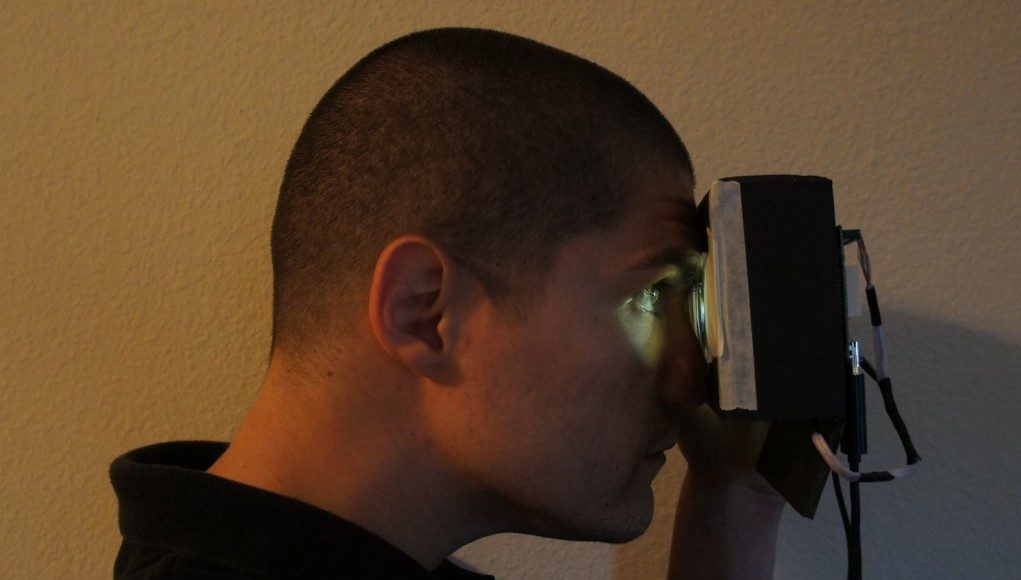

Download AutoCAD Case Template Download PDF Case TemplateImportant Note: One concern when building a HMD is that everyone has a different intra-pupillary distance, or IPD, which is the distance between your pupils. There are two ways to address this issue, one is to make the distance between the lenses adjustable, which is quite tricky on a DIY budget, the other is to use optics with a wide exit-pupil so most people can use the HMD without adjustment. The latter is the method used by both the Rift and by our DIY project. Invariably, some people will fall outside the range of supported IPDs and some adjustments will be necessary. For maximum optical clarity I recommend that you take a measure of your IPD and make the adjustments to the provided AutoCAD file before moving to the next step. Once you open the file, you will notice a dotted line connecting the center of the two circular cutout for the eyes, by double-clicking that line you can enter your own IPD (in millimeters).

The PDF file that we will use as a cutting guide looks like this:

Cut and Build the foam-core case:

- If you made adjustments to the AutoCAD file, first export it to PDF.

- Download and install Adobe Reader or any PDF reader that supports printing in “poster mode”.

- Make sure to print at 100% scale, in poster mode and with cut-marks enabled.

- Tape all 4 pages to a 4mm tick sheet of foam-core using transparent masking tape.

- Using an X-Acto knife, cut out the lens openings completely first. The easiest way to cut a clean circle is to lay the foam-core sheet over a stack of scrap paper then use the knife to punch several holes around the line of the circle, always making sure each hole connects with the previous one. Next turn the sheet around and use the small holes on the other side as a guide to cut the circle by connecting the dots.

- Next mark all other lines with a shallow cut – but don’t cut through yet!

- Cut through all outside lines to separate the shell from the rest of the sheet.

- Finally we must deal with the internal lines which are fold lines and are a bit trickier since they must be v-cut. It is not as hard as you think, just make sure to practice a few v-cuts on a spare piece before moving on.