VR shooters like Onward, Pavlov, and sport shooting game Hot Dogs, Horseshoes & Hand Grenades are fun ways to blow off a little steam and put some lead down range, but if you aren’t already using a modular stock, and have access to a 3D printer (or at least $100 for a pre-built), then you might be missing out.

VR stocks are admittedly a bit fiddly, and really don’t feature native plug-and-play support for any game, but they’re still a great way of increasing your immersion (and aim) in VR shooters if you have the time and money to get things right.

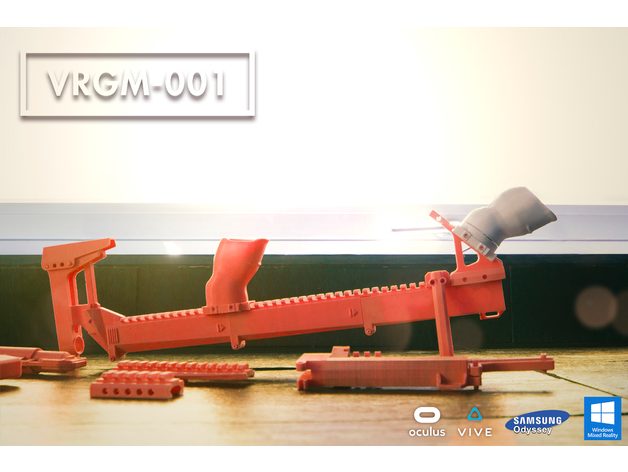

There are a few great 3D-printable stocks already out there on Thingaverse, but one of the slickest we’ve seen yet it the VRGM, a stock design created by João Brito that can be printed to fit Oculus Touch, HTC Vive, and Windows VR controllers.

It’s been on Thingaverse since March, but Brito has been steadfast in providing constant refinements to his design, showing an awesome amount of dedication that has pushed his project into near consumer-level fit and finish.

The VRGM is touted for its economic and lightweight design, weighing as much as a single Oculus Touch controller (~165 g, ~5.8 oz). The design is modular, and also fully 3D printable so you don’t need to substitute in a poll for the main bar. Grips can be fitted with neodymium magnets, and also provides areas for handy attachments like bi-pods and a pump-action rail.

Brito used a Prusa Mk1 printer, printing at .20 resolution with an infill of 5-10% for all parts outside of the stock mount (25% infill), MT-1 tube (25% infill), and sniper stock (15% infill).

You can check out VRGM on Thingaverse here. Don’t Miss the in-depth build guide either.

Pre-built Stocks

Don’t have a 3D printer? There’s also a few pre-built VR stocks out there that should get you up and running for around $100.

ProTube offers a build-it-yourself kits for €60 (~$68) for motion controllers including Oculus Rift, HTC Vive, PSVR, and Windows VR. Pre-built stocks will cost you a bit extra at €80 (~$91), and you can also go for the tricked out carbon fiber model for €120 (~$136).

Mamut’s injection-molded gun stocks are also something worth looking at if you have the cash. With a €65 (~$74) Mamut neodymium magnet bracket and carbon fiber tube for HTC Vive or Oculus Rift combined with their butt & cheek rest attachment €25 (~$28), you’ll have a full stock ready to go which approaches the same utility of the VRGM.

Ever cheaper is the Virtual Core carbon fiber Evolution Rifle Adapter for HTC Vive and Oculus Rift variant coming in at $60 a piece, although shipping may add a significant expense the farther you live away from its shipping destination in Florida.

Again, these aren’t your standard aftermarket peripherals that can offer any appreciable level of native support through games, but if you’re head over heels for a certain VR shooter and want to up your game, you may want to think about the options above.

You can of course always hack a broom stick in half and create a duct tape monstrosity too—whatever it takes to crush your enemies, see them driven before you, and to hear the lamentations of their women, men, cats, dogs, etc.

Know of any more great 3D prints for VR? Did we miss any great pre-built stocks on the market? Make sure to leave us a comment below.