A new chip that Valve is recommending for use in future SteamVR headsets and accessories brings improved performance and significant power reduction compared to the first generation solution along with potential manufacturing savings.

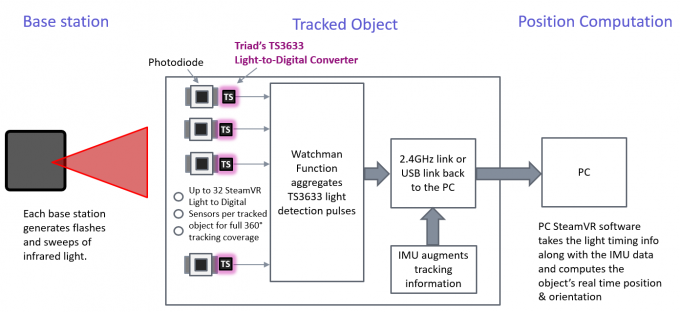

An essential component in the first generation HTC Vive is the cratered sensors that cover the headset and controllers. Each of these sensors consists of a photodiode and discrete circuit which detects and interprets pulses of light from the Lighthouse ‘basestations’. Elegant as the system is, there’s room for improvement in the sensor design; a new chip that Valve is recommending for use in future SteamVR tracked headsets and peripherals brings enhancements ranging from reduced costs to improved performance and power savings.

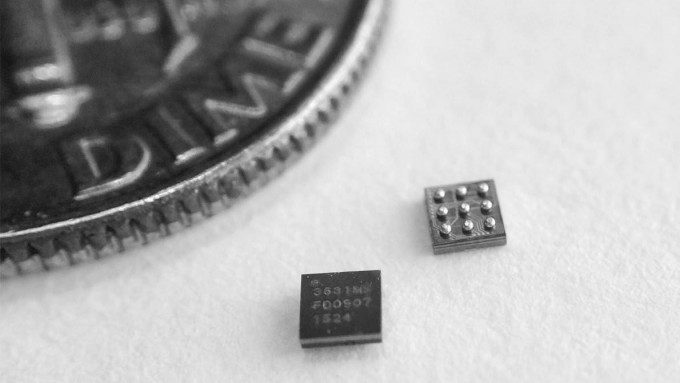

That chip is the TS3633 integrated circuit from Triad Semiconductor, a US firm which specializes in creating custom analog and mixed signal integrated circuits. We learned recently that Valve worked with Triad to architect the chip, and that it sits next to the photodiode as an interpreter of the raw signals from the Lighthouse basestations. The TS3633 is now available for purchase from Triad, and we’re learning more about what improvements it brings to the table for future headsets using SteamVR Tracking.

Cost

While first-generation VR headsets are impressive, they’re still priced in the enthusiast realm with the Oculus Rift at $600 and the HTC Vive at $800. Like the smartphone, widespread adoption of VR headsets will come as the devices, and the components in them, mature and become less expensive and easier to manufacture.

The first generation HTC Vive—the first (and so far, only) VR headset using SteamVR tracking—uses a discrete circuit sensor design consisting of 41 individual components. The TS3633 cuts that number down to 9, which means more streamlined manufacturing.

Triad’s VP of Marketing & Sales, Reid Wender, explained that the chip is cost-optimized for high volume manufacturing. For a complete system (including headset and controllers), which has around 80 sensors, the chip reduces component placements by 2,560 over the 41 component per-sensor design of the first-generation Vive. That brings savings in component placement and also opens the door to simplifying circuit board designs which can further reduce cost, says Wender.

Less components can also mean better reliability which can cut down further on tangential costs that go beyond the price of a device’s components alone.

“The more components in a system the more likely there will be a manufacturing yield problem or field reliability problem,” said Wender. “The circuit boards that these devices are implemented on are relatively expensive. Removing the 2,560 placements means that the final assembly will have a higher yield and require less expensive manual rework. And, fewer components means better reliability in the field and lower warranty costs.”

Performance

Wender explained that the Triad chip is more capable across a range of abilities that are important to the SteamVR Tracking technology, ultimately delivering improved tracking performance.

“The TS3633 excels on several technical characteristics such as detected pulse width versus distance, more sensitivity for longer range detection, better off angle detection, improved optical sync detection, improved start of sync detection, and improved centroid location,” he said. “All of these technical improvements equate to a more robust SteamVR Tracking experience with observably improved user experience.”

I had suspected that increasing the size of the sensor’s photodiode would be an obvious way to improve tracking performance and range, but Wender explained why this might not be the ideal approach with a useful analogy:

You can think of the system as radio system with a link budget. The basestations are the transmitters and the tracked objects are the receivers. Extending this analogy, the photodiode takes the place of the antenna that would be there in an RF system. The Triad TS3633 is the front end of the receiver that provides ‘lots of amplification, filtering and extracts the signal from the noise.’ So, instead of simply making the photodiode larger (slower, more expensive overall system) it may be a better-engineered system (lower jitter, higher performance, lower cost, smaller size) to have a somewhat smaller, faster photodiode and get more sensitivity & gain from the Light-to-Digital converter IC.

Continue Reading on Page 2 >>

Page: 1 2